Keep transcending and seek for perfection.

Suitable for fiber cement board production line, calcium silicate board production line, fiber cement pressure board production line, calcium silicate board equipment, etc., for primer, top paint roller coating and coloring. The paint film treated by this machine has smooth surface, good saturation, no pile paint before and after, which can be almost the same as the spray coating effect, but the thickness of the top paint is greatly reduced, only the thickness is about 6-25g/m2, and the spray coating has 80-180g/m2. In contrast, the fiber cement board coating production line is actually a cost-saving tool. Conveyor belt and rubber wheel, electro-optical wheel by imported motor, inverter speed, so that paint smoothness, film thickness more precise control. The coating wheel adopts quick disassembly type, easy to change, accurate positioning, and the height adopts counting meter reading. It can know more about the plate of different thickness, and the operation is natural and convenient. The Angle of the imported scraper is adjusted by the micro worm gear reducer, and the distance between the smooth roller and the rubber wheel is adjusted by the worm gear. Equipped with three inverter or optional PLC, each group can be used separately, processing better UV dryer

It is suitable for paint drying after UV coating on fiber cement board production line, calcium silicate board production line, fiber cement pressure board production line, calcium silicate board equipment, etc. Instant drying, no waiting for drying time, greatly shorten the coating process time, coating surface hardness, bright color. With the coater directly, the machine can be connected to the drum type or curtain type coater, the finished product directly dry, avoid the trouble of handling. The machine adopts imported high pump UV lamp and imported reflector, the lamp irradiation intensity is strong or weak, and the reflector can have a high reflection of 99% lamp source. At the same time, high-strength capacitors and transformers are configured to greatly enhance the stability of UV lamps. The conveying method is steel Teflon, stainless steel conveyor belt or roller conveying method. Equipped with a cooling system, the temperature controller controls the internal high temperature of the chassis, so that it will not be deformed in high temperature environment for a long time. The entrance and exit of the side panel are equipped with a light shield to effectively prevent the leakage of ultraviolet rays.

Zhengzhou Amrit machinery manufacturing company

Zhengzhou Amlite Machinery Manufacturing Company

Amulite

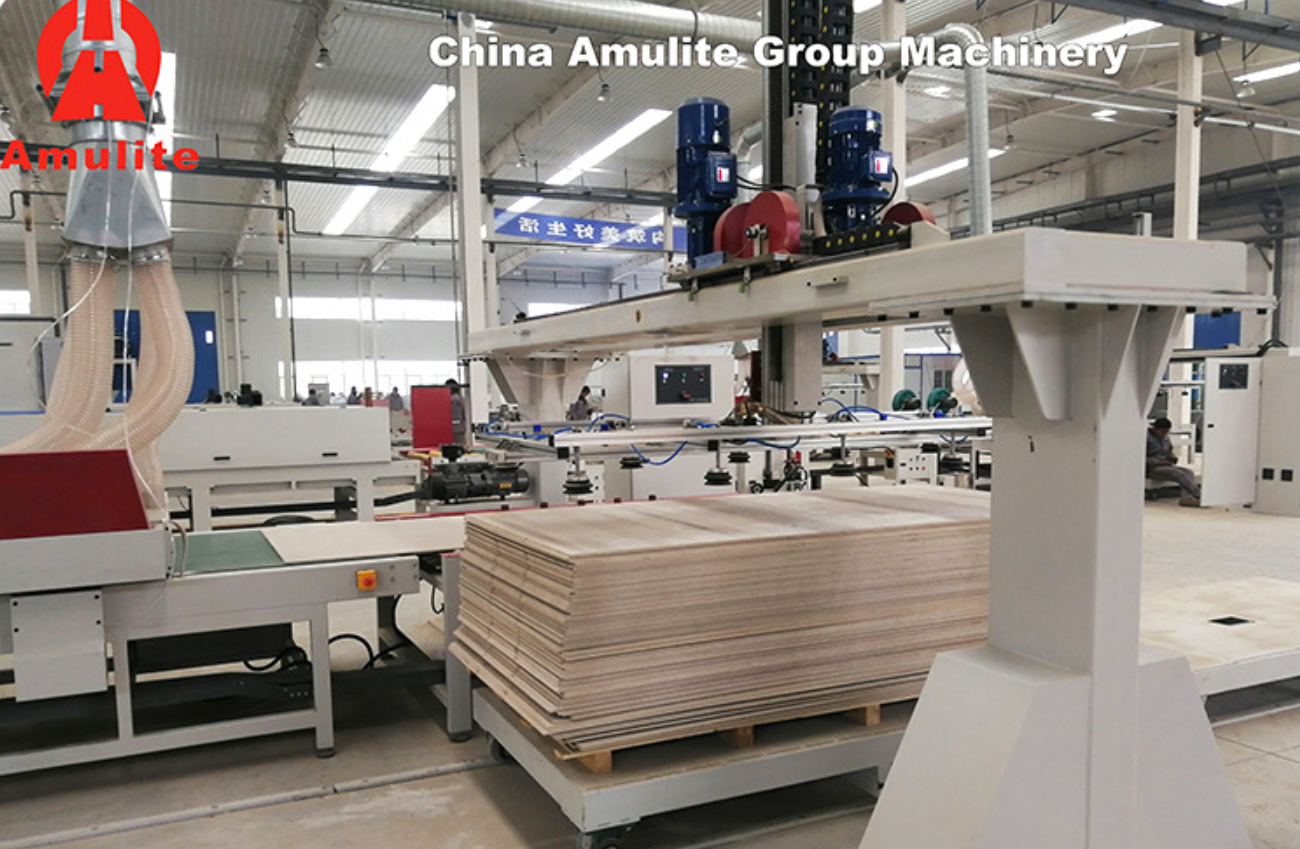

Zhengzhou Amrit Machinery Manufacturing Company is a machinery factory focused on the design, manufacture and supply of high quality mechanical equipment and solutions. Over the years, we have accumulated a wealth of experience and expertise in the field of mechanical engineering. As an innovative company, we are constantly working to introduce different technologies and processes to ensure that our products are at the forefront of the industry. We have a team of engineers, designers and technical experts with a wide range of expertise and practical experience. They are not only able to meet the specific needs of their customers, but also provide innovative solutions to meet changing market demands. Our product range is wide, covering various types of mechanical equipment, including fiber cement board production line, calcium silicate board production line, asbestos tile production line, cement tile production line, EPS cement composite board production line, glass magnesium board production line, gypsum board production line, cement hollow wall board production line.

Zhengzhou Amrit machinery manufacturing company

Zhengzhou Amlite Machinery Manufacturing Company

Call + 8615324995777 whatsapp8615324995777 Amulite24 hours service

Previous:[News]